Technical Info

General data

HOME > Technical Info > General data

Recommend condition for Carbide Reamer

Recommend condition for Carbide Reamer

| Workpiece | Diameter (mm) | Cutting condition | ||

|---|---|---|---|---|

| Quality of material | Tensile strength (Kg/mm2) / Hardness (HB) |

V (m/min) | f (mm/rev) | |

| Carbon steel | ~ 100 | ~10 10~25 25~40 |

8 ~ 12 | 0.15 ~ 0.25 0.20 ~ 0.40 0.30 ~ 0.50 |

| 100 ~ 140 | ~10 10~25 25~40 |

6 ~ 10 | 0.12 ~ 0.20 0.15 ~ 0.30 0.20 ~ 0.40 |

|

| Cast steel | 40 ~ 50 | ~10 10~25 25~40 |

8 ~ 12 | 0.15 ~ 0.25 0.20 ~ 0.40 0.30 ~ 0.50 |

| 50 ~ 70 | ~10 10~25 25~40 |

6 ~ 10 | 0.12 ~ 0.20 0.15 ~ 0.30 0.20 ~ 0.40 |

|

| Cast iron | ~ 200 | ~10 10~25 25~40 |

8 ~ 15 | 0.20 ~ 0.30 0.30 ~ 0.50 0.40 ~ 0.70 |

| 200 ~ | ~10 10~25 25~40 |

6 ~ 12 | 0.15 ~ 0.25 0.20 ~ 0.40 0.30 ~ 0.50 |

|

| Aluminum alloy | ~10 | 15 ~ 25 | 0.20 ~ 0.30 0.30 ~ 0.50 0.40 ~ 0.70 |

|

| 10~25 25~40 |

20 ~30 | |||

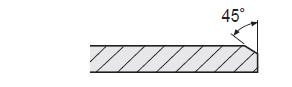

Effect on chamfer

Effect on chamfer

| Shape | Feature |

|---|---|

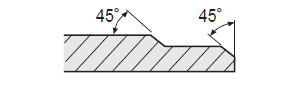

|

If Feed stopped on Sharpe edge of flute, it make mark on machine surface. |

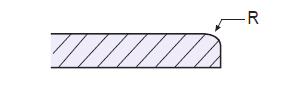

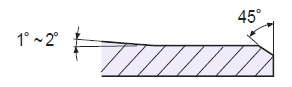

|

The work surface of R is good, but the work surface of R is difficult, and vice versa. |

|

It is called a double-edged shape. The chip can be created in two layers and produce good results, but it is difficult to regrinding. |

|

1 to 2 in the information section of the cutting edge, the cutting edge is long and Tool life is limited. A good effect can be obtained from finish machining. |

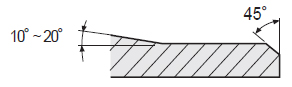

|

The second-tier guidebook is 10 to 20。 It is economical because the Cutting Flute is relatively short and has a long distance. |

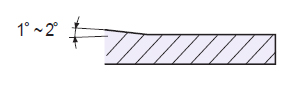

|

Used for finish machining and applied to hand reamer. |

Effect on Helix

Effect on Helix

| Helix direction | Feature |

|---|---|

| Straight angle(Helix angle 0°) | ㆍNormally surface is rough without cast iron. |

| The right Helix angle flute | ㆍGood machinability and good chip emission. ㆍThere is a wide area of application of workpiece. ㆍExcellent in high hardness workpiece. |

| The left Helix angle flute | ㆍSurface roughness is good for aluminum, copper, and copper alloy. ㆍEffective to workpieces of light material. |

Trouble Shooting

Trouble Shooting

| Trouble issue | Cause | Solution |

|---|---|---|

| Big hole | Maximize effect on burnishing |

|

| Hold down the occur Built-up edge. |

|

|

| Reduces the imbalance in cutting force. |

|

|

| Small hole | Reduce the finish effect |

|

| Roughness | Reduce the Chattering. |

|

| Surface roughness faulty | Enlarge on Burnishing. |

|

| Remove the fusion. |

|

|

| Remove the chattering. |

|

|

| Remove chip interference. |

|