Technical Info

General data

HOME > Technical Info > General data

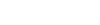

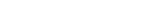

WH THREAD

WH THREAD

WIDIN specific tabs can be selected to suit the working conditions by applying a step-by-step method of the unique WH method to satisfy a certain degree of female screw.

P≤0.6(40 over) {p≤ 0.6(T.P.I≥40)}

above tolerance : 0.010 + 0.015 x n

below tolerance : above tolerance -0.015

measure :mm

P≥0.7(36 below) {p≤ 0.7(T.P.I≤36)}

above tolerance : 0.020 x n

below tolerance: above tolerance -0.020

measure :mm

Case M3×0.5

Case M10×1.5

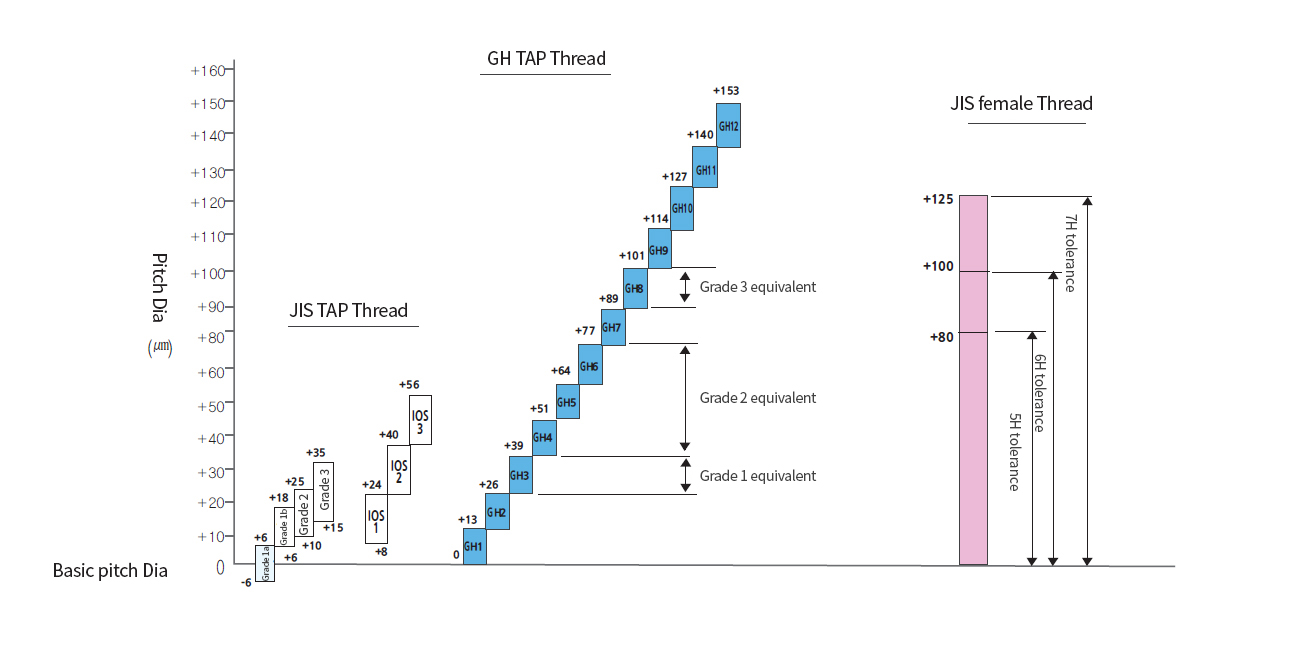

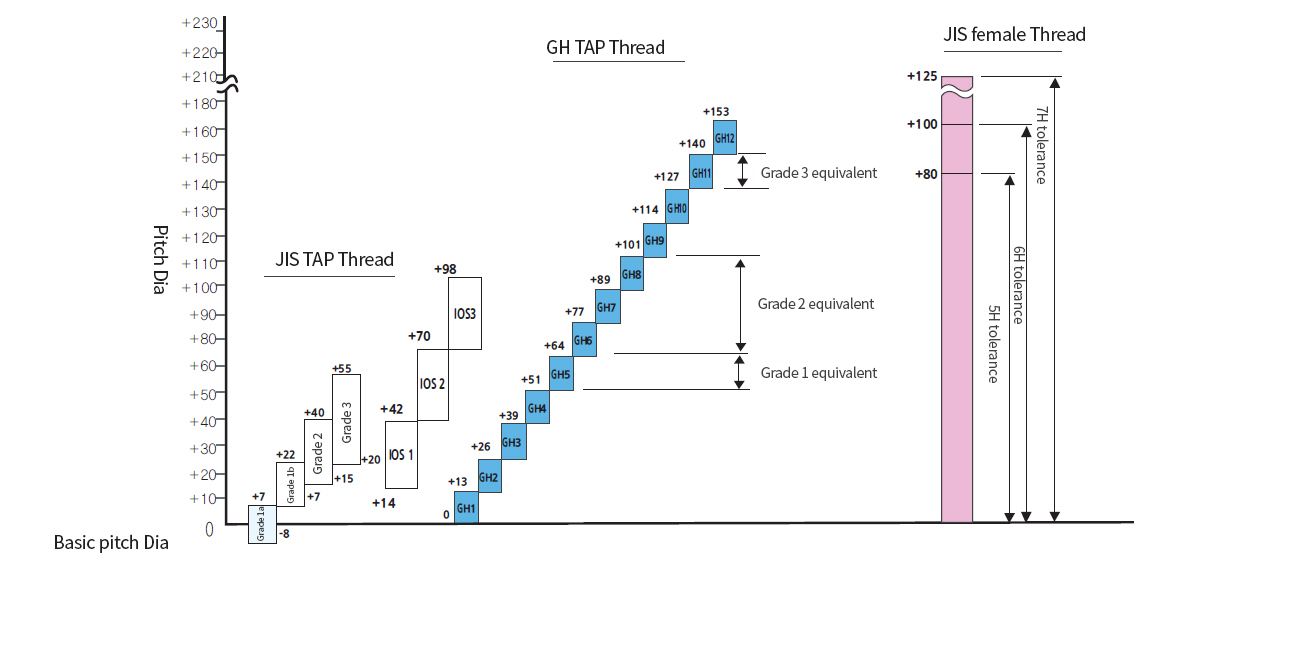

GH Thread

GH Thread

The non-groove tab (roll tab) requires strict bottom diameter management, unlike the cutting tab. Also the female screw is machined by plastic deformation, and the degree of strict tap thread is applied. WIDIN adopted stepwise thread of 12.7 μm (0.0005) tolerance.

Case M3×0.5

Case M10×1.5

Cutting Speed and Cutting emulsion

Cutting Speed and Cutting emulsion

The cutting speed depends on various conditions, such as tap material, type, acid water, bottom shape, workpiece, and cutting emulsion and sufficient care must be taken when applying.

The cutting emulsion also has three actions: lubrication, cooling, and semi-welding, which is called the three elements of cutting oil.

Since taping involves very complex cutting, supply sufficient workpiece emulsion for processing.

Cutting Speed and Cutting emulsion

| Workpiece | Cut Speed (m/min) | Non-aqueous | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Straight Tabs | Spiral Tabs | Point Tabs | Carbide Tabs | Roll Tabs | HighSpeed Synchro Tap |

Pipe Thread Tap |

Emulsion | Emulsion | Semidry | Dry | ||

| Low-carbon steel | CO,25% and below |

8~13 | 8~13 | 15~25 | - | 8~13 | 27~32 | 3~6 | ◎ | ○ | △ | △ |

| Medium-carbon steel | CO,25~ 0.45% |

7~12 | 7~12 | 10~15 | - | 7~10 | 27~32 | 3~6 | ◎ | ○ | △ | △ |

| High-alloy steel | More than CO,4.5% |

6~9 | 6~9 | 8~13 | - | 5~8 | 22~27 | 2~5 | ◎ | ○ | △ | △ |

| Stainless steel | SCM | 7~12 | 7~12 | 10~15 | - | 5~8 | 22~27 | 2~5 | ◎ | △ | △ | △ |

| Tool steel | 25~45 HRc |

3~5 (4~8) |

3~5 (4~8) |

4~6 (6~10) |

- | - | 15~20 | 2~5 | ◎ | △ | - | - |

| Stainless steel | SUS | 4~7 | 5~8 | 8~13 | - | 5~10 | - | 3~6 | ◎ | ○ | - | - |

| Stainless steel with precipitation hardening | SUS630 SUS631 |

3~5 | 3~5 | 4~6 | - | - | - | 2~5 | ◎ | - | - | - |

| Tool steel | SKD | 6~9 | 6~9 | 7~10 | - | - | - | 2~5 | ◎ | - | - | - |

| Cast iron | SC | 6~11 | 6~11 | 10~15 | - | - | 17~22 | 2~5 | ◎ | ○ | - | - |

| Cast iron | FC | 10~15 | - | - | 10~20 | - | - | 2~5 | ◎ | ○ | ○ | ○ |

| Ductile cast iron | FCD | 7~12 | 7~12 | 10~20 | 10~20 | - | - | 4~8 | ◎ | ○ | ○ | - |

| Bronze | Cu | 6~9 | 6~11 | 7~12 | 10~20 | 7~12 | 27~32 | 2~5 | ○ | ○ | - | - |

| Brass and Brass castings | Bs, Bsc | 10~15 | 10~20 | 15~25 | 15~25 | 7~12 | 27~32 | 5~10 | ○ | ○ | ○ | ○ |

| Bronze and Bronze castings | PB, PBC | 6~11 | 6~11 | 10~20 | 10~20 | 7~12 | - | 6~11 | ○ | ○ | - | - |

| Bronze and Bronze castings | AL | 10~20 | 10~20 | 15~25 | - | 10~20 | 100~300 | 5~10 | ◎ | ○ | △ | - |

| Aluminum alloy castings | AC, ADC | 10~15 | 10~15 | 15~20 | 10~20 | 10~25 | 80~300 | 10~15 | ◎ | ○ | △ | - |

| Magnesium alloy castings | MC | 7~12 | 7~12 | 10~15 | 10~20 | - | - | 10~15 | ◎ | ○ | ○ | - |

| Zinc Gold Casting | ZDC | 1~12 | 7~12 | 10~15 | 10~20 | 7~12 | 27~100 | 10~15 | ◎ | ○ | △ | - |

| Thermosetting plastic | Bakelite phenol epoxy | 10~20 | - | - | 15~25 | - | - | 5~10 | - | ○ | ○ | ○ |

| Thermoplastic Plastic | Vinyl chloride nylon | 10~20 | 10~15 | 10~20 | 10~20 | - | 27~32 | 5~10 | - | ○ | ○ | ○ |

◎: Optimum / ○:application / △: available / - : unavailable

Meter Screw Recommended Drill Diameter Sheet (Based on Grade 2 Screws)

Straight Tabs, Spiral Tabs

| Size name Thread Size |

Recommend Drill Dia Drill Size(mm) |

Reference Drill Dia(mm) | |

|---|---|---|---|

| Minimum(min) | Maximum(max) | ||

| M3 X 0.5 | 2.50 | 2.459 | 2.599 |

| M4 X 0.7 | 3.30 | 3.242 | 3.422 |

| M5 X 0.8 | 4.20 | 4.134 | 4.334 |

| M6 X 1.0 | 5.00 | 4.917 | 5.153 |

| M8 X 1.25 | 6.80 | 6.647 | 6.912 |

| M10 X 1.25 | 8.80 | 8.647 | 8.912 |

| M10 X 1.5 | 8.50 | 8.376 | 8.676 |

| M12 X 1.0 | 11.00 | 10.917 | 11.153 |

| M12 X 1.25 | 10.80 | 10.647 | 10.912 |

| M12 X 1.5 | 10.50 | 10.376 | 10.676 |

| M12 X 1.75 | 10.30 | 10.106 | 10.441 |

| M14 X 1.5 | 12.50 | 12.376 | 12.676 |

| M14 X 2.0 | 12.00 | 11.835 | 12.21 |

| M16 X 1.5 | 14.50 | 14.376 | 14.676 |

| M16 X 2.0 | 14.00 | 13.835 | 14.21 |

| M18 X 1.5 | 16.50 | 16.376 | 16.676 |

| M18 X 2.5 | 15.50 | 15.294 | 15.744 |

| M20 X 1.5 | 18.50 | 18.376 | 18.676 |

| M20 X 2.5 | 17.50 | 17.294 | 17.744 |