Technical Info

General data

HOME > Technical Info > General data

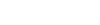

Endmill’s concept

Endmill’s concept

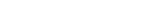

Cutting speed calculation

Cutting speed calculation

Endmill Regrinding

Endmill Regrinding

Regrinding timing

| Range of application | Endmill Dia | Abrasion loss |

|---|---|---|

| Finish machining | ~ ø10 ø 11 ~ ø30 ø 31 ~ ø50 |

0.05 ~ 0.1 0.1 ~ 0.25 0.2 ~ 0.35 |

| Roughing machining | ~ ø10 ø 11 ~ ø30 ø 31 ~ ø50 |

0.08 ~ 0.15 0.15 ~ 0.35 0.3 ~ 0.45 |

Way to regrinding

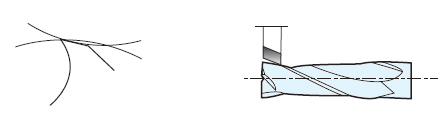

- (1) Concave type

- ㆍDemand to close Dia tolerance

ㆍFavorable machinability.

ㆍNeed to 2nd rake Clearance angle

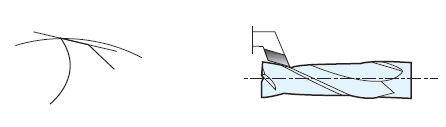

- (2) Concave type

- ㆍFavorable machinability

ㆍNeed to 2nd rake Clearance angle

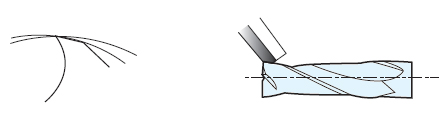

- (3) Eccentric Type

- ㆍFavorable Flute Diameter

ㆍExcellent Surface Roughness on workpiece

ㆍNot necessary for secondary clearance on rake

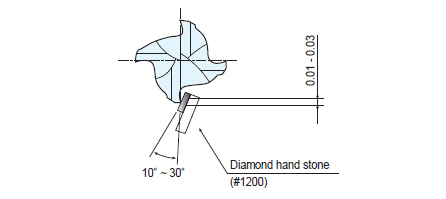

Honing

- Honing

- 1) Recommended for machining mold steel or high hardness workpiece.

2) When machining without honing, process it for 10 to 30 seconds with

an slotting of 0.01mm or less before entering the normal speed.

Endmill trouble shooting

Endmill trouble shooting

| Troble issue | Cause | Solution |

|---|---|---|

| Broken |

|

|

| Wear and burr |

|

|

| Vibration during cutting |

|

|

| Defection for flute |

|

|

| Bad cutting performance |

|

|

| Poor chip emission |

|

|

| Burr on the surfacce |

|

|

| Shape faulty |

|

|

| Built up edge |

|

|